Identifying and Addressing Electrocoating Defects

September 21, 2021

Corrosion Resistant Electrocoating

October 19, 2021Electrocoating, Improving the Process

A Growing Market

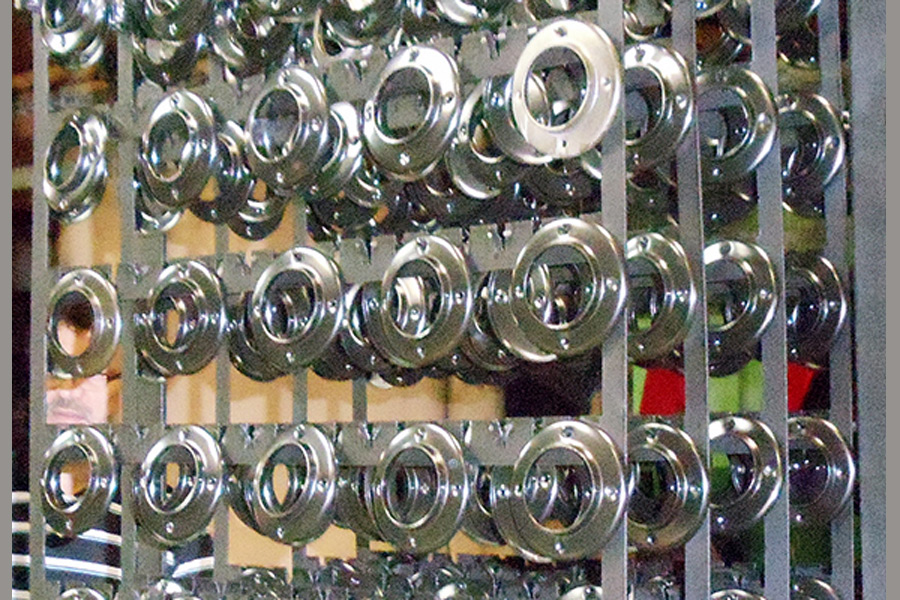

Electrocoating is a wet process in which manufactured components or parts are racked and lowered into an aqueous solution containing electrically charged particles. By regulating the voltage, a precise thickness of paint can be applied to the parts, which are then cured in an oven.

E-coating is used worldwide to coat products in a variety of industries, including automotive, appliance, marine, and agriculture.

Demand from manufacturers continues to grow and is expected to reach $4.6 billion by 2024.

Advancing Electrocoat Technology

Much of the growth of electrocoating is attributed to the development of cathodic acrylic electrocoating. In this e-coat technology, positively charged paint is deposited on an electrically conductive substrate (the manufactured part) from a cathodic paint bath using direct current.

Cathodic acrylics provide good UV protection, resulting in even more durable coatings, such as parts used in outdoor environments.

Bulk processing is another advancement in recent years. Where racking large quantities of small parts is often impractical, the latest e-coat paint formulations and the development of new conveyer systems allow for the processing of parts in bulk. Bulk e-coating techniques help minimize excess fill in parts with recesses, eliminating a common problem of dip-spin coating systems.

Understanding and Controlling Parameters

While durable, affordable, and environmentally friendly, e-coating is a complex process governed by a wide range of parameters. Examples of variables include the main bath % of solids, tank level, temperature, pH, UF flux rate, water conductivity, and anolyte conductivity.

Water quality can affect anode wear and cause coating defects, and some paints require acid additions to control pH. Different e-coat types specify different bath temperatures, which is affected by the size of the heat exchanger, the temperature of the cooling water, and the flow rate through the heat exchangers.

When a variable goes out of range anywhere in the process, the result can be a defective coating run, wasted time, and added expense.

Delivering a cost-effective, consistent result, batch after batch, requires an experienced electrocoating service with a proven, well-calibrated production line.

Experienced Electrocoating Professionals

At Great Dane Powder Coating, Inc., we are celebrating 27 Years in business in 2021. Our e-coating specialists are trusted by fabrication facilities and manufacturers across the country to deliver highly durable coatings on a wide variety of parts and components

Challenge us today! Call Great Dane Powder Coating at 724-537-9709 or visit our New eCoat Customer page for more information.

Interested?

Call us today at 724-537-9709 or click a button below.