Nomination – Community Employers of the Year 2021

August 31, 2021

Electrocoating, Improving the Process

October 5, 2021Identifying and Addressing Electrocoating Defects

Has your company tried e-coating products only to experience cratering, rupturing, roughness, pin holes, or other defects?

Great Dane Powder Coating’s team of electrocoating experts have the experience to deliver the highest levels of quality control and troubleshooting for every order.

Check out our latest article on Troubleshooting Electrocoating to learn how we understand and address the defects possible with electrocoating, as well as take proactive measures to assure a quality result.

Common Problems and Simple Fixes

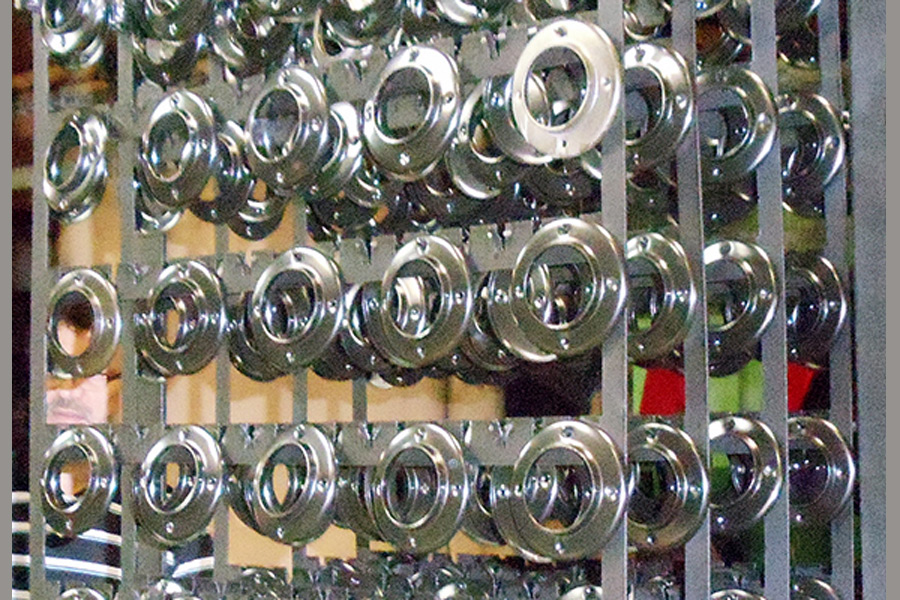

The “wet” e-coating process is not immune to occasional problems. Although it’s widely viewed as the most precise coating process, unexpected defects can occur during and after dipping.

Some of the most common electrocoat defects include:

- Cratering – bowl-shaped depressions with material in the center and raised, circular edges. These typically occur due to contamination in the bath or rinses. Cratering can be solved through applying oil-absorbent media, contaminant dilution, and more.

- Rupturing – the bursting of film due to excessive heat and electrical sparking/gassing. It is typically caused by excessive voltage or ripples and can be solved by adjusting the voltage or ultra-filtering the tank.

- Roughness – indicated by patchy, non-uniform spots on an otherwise smooth surface. Roughness can be caused by ionic contamination, low solvent levels and substrate irregularities, and it’s most easily solved by improving water quality, adding solvents, or controlling pretreatment.

- Pin holing – displays a random patch of small, volcano-like holes in the electrocoat film. Also known as outgassing, it is often caused by poor metal quality or rectifier problems and can sometimes be difficult to address.

Fortunately, the Great Dane team is well-versed in proactively avoiding these problems and quickly addressing any issues that should arise. From redissolution to dirt contamination; streaking to foaming, and everything in between, we handle it all!

Great Dane is prepared to handle even the toughest electrophoretic coating defects through our expert troubleshooting process. When you want quality coating done right, call us at 724-537-9709.

Celebrating 27 Years of Excellence in 2021

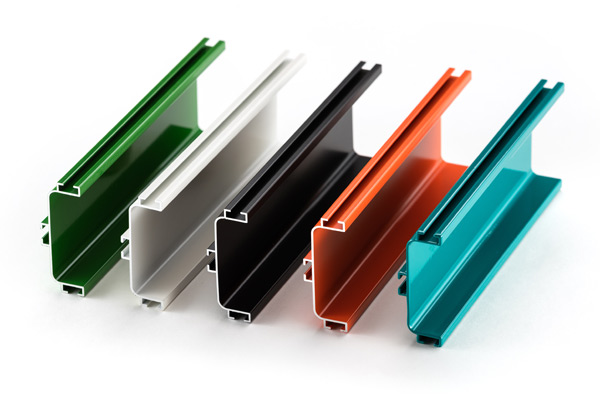

At Great Dane Powder Coating, Inc., we have a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our Contact Us page today.

Interested?

Call us today at 724-537-9709 or click a button below.