Electrocoating Benefits

February 22, 2022

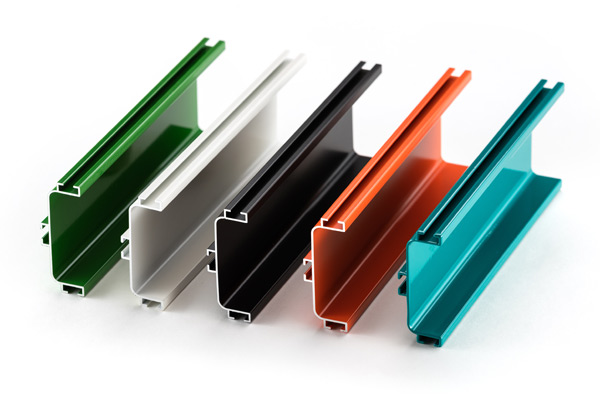

eCoating vs. Powder Coating

March 22, 2022Troubleshooting Electrocoating

A Near-Perfect Process

A Near-Perfect Process

At Great Dane Powder Coating Inc., we are experts in professional electrophoretic coating. E-coating is an affordable, durable, and near-perfect parts coating process.

Unfortunately, “near-perfect” still leaves room for occasional defects, coating flaws that can compromise e-coat’s protective and decorative finish.

That’s why it’s so important to work with experienced professionals whose skills include effectively troubleshooting the electrocoating process.

The wide range of possible defects in electrocoating includes:

- Cratering

- Rupturing

- Roughness

- Redissolution

- Dirt/streaking

- Pin holing/outgassing

- Foaming/air entrapment

- Gloss/color variations

- Throwing power faults

- Thin coating/orange peel contamination

When problems arise, understanding what went wrong and how to fix it can sometimes be challenging. At Great Dane Powder Coating Inc., we are proud of our team’s ability to proactively avoid defects and to quickly understand and address e-coating flaws when they do occur.

Understanding and Addressing Defects

In order to develop solid solutions to electrocoating problems, using the right troubleshooting process is key.

Five common e-coating troubleshooting steps are:

- Defining the problem – asking the right questions about what type of defect your e-coating is experiencing, such as its consistency and timing.

- Identifying the root cause – determining whether the problem is mechanical or procedural by researching the entire process.

- Determining corrective action – developing a logical plan which methodically tests each variable to help identify possible solutions.

- Implementing the corrective action – determining which solution(s) can be applied, or if the process must restart.

- Following up – making any necessary, permanent changes to prevent the problem from reoccurring.

Knowing how things can go wrong and how to deal with problems is at least as important as knowing what to expect under ideal conditions. The Great Dane team understands troubleshooting should not just be reactionary; but rather a proactive step toward protecting electrocoated parts from defects.

The E-Coat Advantage

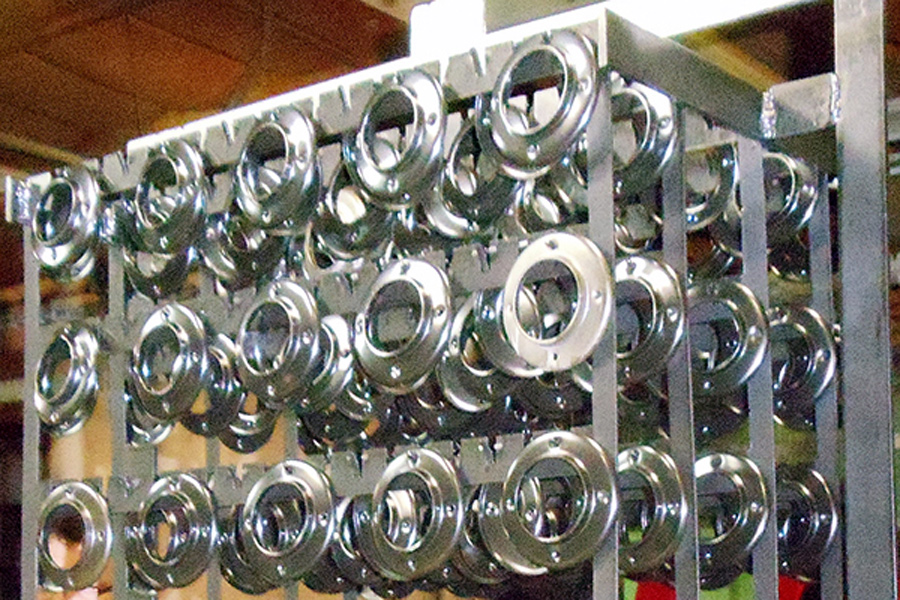

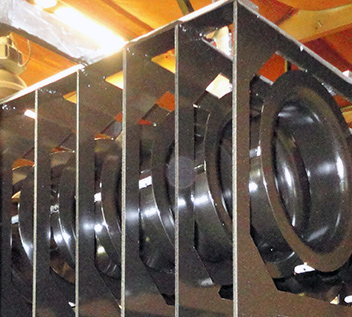

Also known as e-coating or electropainting, electrocoating is a great option for applying a high-quality finish to industrial parts and a wide range of metal components.

While powder coating is a dry process, e-coating is often referred to as a “wet” one, as metal parts are immersed in a bath of paint or epoxy. Electric currents are then applied to attract the particles to the metal.

E-coating allows for application of thinner coats, as they can be precisely controlled by regulating the current. The parts are then cured in an oven to ensure an attractive, uniform finish of the highest quality.

The “wet” dipping process allows the film coating to reach every nook and cranny, no matter how complex the parts are. Great Dane’s electrophoretic coating options can evenly finish the most complex shapes in hard-to-reach areas.

Experienced Powder Coating Professionals

At Great Dane Powder Coating, Inc., we have over 27 years of experience! Our powder coating specialists are trusted by fabrication facilities and manufacturers across the country to deliver highly durable coatings on a wide variety of parts and components

Challenge us today! Call Great Dane Powder Coating at 724-537-9709 or visit our Contact Us page for more information.

Interested?

Call us today at 724-537-9709 or click a button below.