When is Electrocoating the Best Option?

January 25, 2022

Troubleshooting Electrocoating

March 15, 2022Electrocoating Benefits

Affordable, Efficient, and Low Waste

The benefits of electrocoating (E-coating) include superior corrosion resistance, controllable, uniform film coverage, and the ability to coat complex parts evenly.

An added advantage of the E-coat process is its high efficiency.

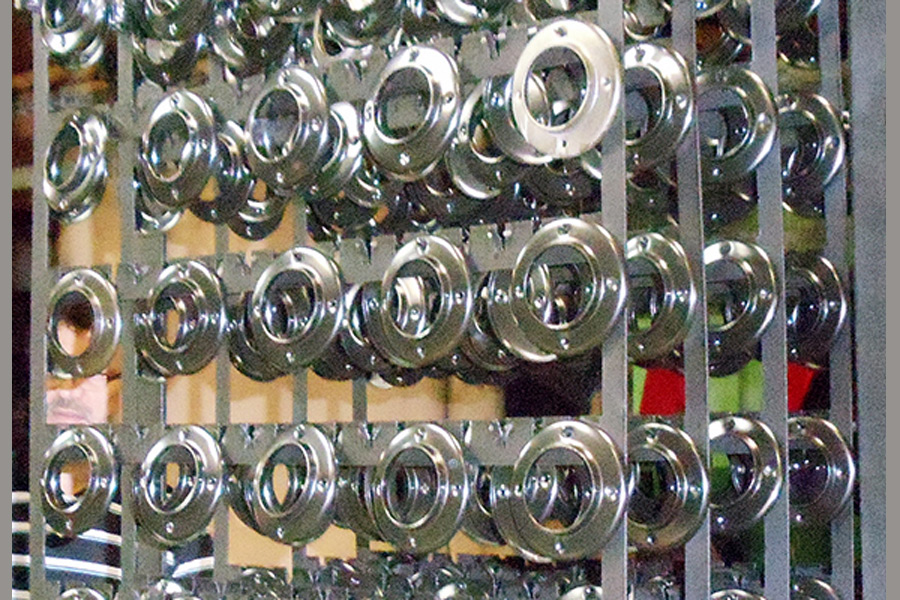

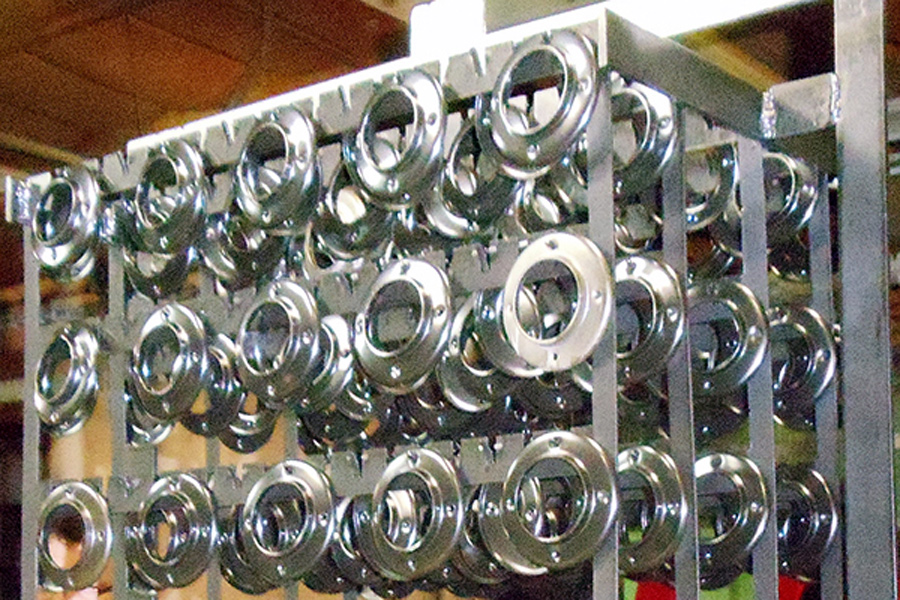

- As many parts as can be racked can be coated at once.

- Virtually all unused paint is recoverable

- Coating thickness is precisely controlled, leading to consistent and uniform coats across multiple product runs.

E-coating is an eco-friendly process and is EPA compliant.

Reduced Manual Labor

Much of the cost savings of E-Coating comes from its savings in labor. Where painting and powder coating require experienced application personnel, electrocoating involves racking and lowering the parts into a solution of waterborne resins.

Because the process draws paint to the part’s surface through an electric charge, there is no need to inspect or re-coat parts due to painting defects like runs, sags and voids.

Highly complex parts can also be efficiently coated in this way, achieving a reliable, uniform coating without requiring an experienced worker to engage in tedious detail work, one part at a time.

By coating parts at a molecular level, E-coating is far less wasteful and more efficient than spraying,

Celebrating 27 Years of Excellence

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and the best equipment. It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our Contact Us page today.

Interested?

Call us today at 724-537-9709 or click a button below.