E-Coat

Electrophoretic, E-coating, Exceptional Results

E-coating, alternately known as electrophoretic painting, electrocoating, and electropainting, is a high-tech process that offers many of the same protective qualities as powder coating with some unique advantages.

Where powder coating uses a dry powder applied as an electrostatic spray, e-coating is a “wet” process where metal parts are immersed in a bath of paint and epoxy. An electric current is applied to attract the particles to the metal, after which the part is cured in an oven.

Advantages include:

Works well to coat complex shapes with hard-to-reach areas.

Coating thickness can be precisely controlled by controlling the current.

Thinner coatings are easier to achieve with an electrophoretic process.

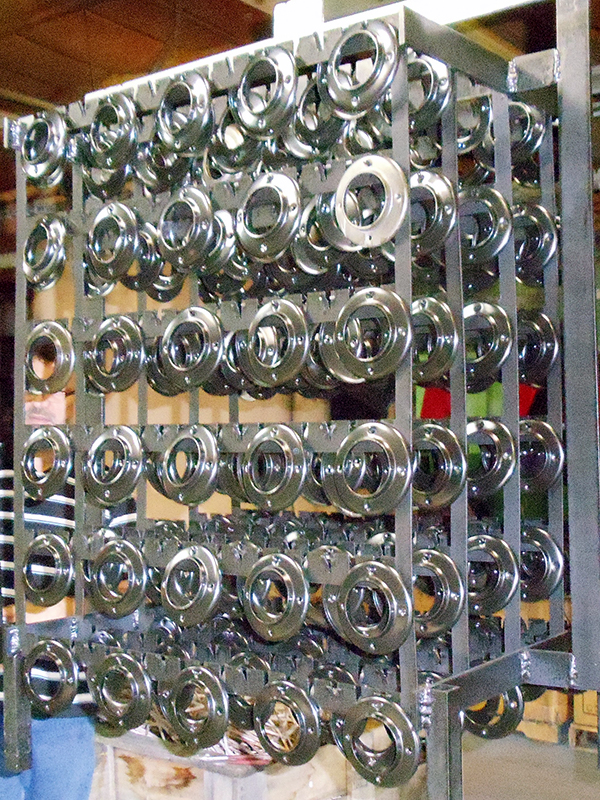

Great for high-production part runs.

Often used as a primer to improve corrosion protection.

Material utilization is close to 100%.

The e-coat process was originally developed for applying an anti-corrosive coating over steel car bodies and has become an important tool for a variety of parts.

How E-Coating Works

The coating materials (resins, pigments, and additives) are dispersed in water and held in a solution. The parts to be coated are immersed and an electrical current is passed through this “bath” using the parts as an electrode.

Electrical activity causes the resin directly in contact with the part to become insoluble in water, leading to deposition of a protective layer. Adjusting the current allows us to control the thickness of the layer, creating a consistent and predictable coating.

The coated parts are then removed from the bath and the coating is cured by baking in an oven to make it hard and durable.

Because the process is water based, there are no flammability problems during application, and no need to dry parts after a water-based cleaning or pretreatment processes.

Recent advancements in electropainting include primers made of low voltage organic compounds, UV protective materials, and improved edge coating.

For high production efficiency coupled with advanced quality results, e-coating is the part coating process of choice.

Our Service Area

Great Dane Powder Coating provides high-quality metal painting services to customers throughout the Pittsburgh region, Western Pennsylvania, Eastern Ohio, West Virginia, Maryland, and New York.

We have clients in Cranberry, Erie, Greensburg, Indiana, Johnstown, Latrobe, Pittsburgh, and Washington, as well as Cleveland Ohio and Morgantown, West Virginia.

Interested?

Call us today at 724-537-9709 or click a button below.