Axalta Aqua EC 6000 Series E-Coat

October 17, 2018

Custom Racking

January 31, 2019Practical Quality Control Testing Methods

No matter what we are coating, these are a few tests in our daily process.

- Film Thickness

- Appearance

Because proper quality control testing is so important to our success and reputation, we administer these tests performed daily, or at least once with every batch of parts.

Powder Coating Film Thickness Testing

A film thickness test determines the thickness of the powder on the part once it’s been cured. This is generally confirmed with a Dry Film Thickness gauge.

A common range we look for is 2-3 dry mils (thousandths of an inch). A coating of 2-3 mils usually provides complete coverage of the powder over the metal.

Powder Coating Appearance Evaluation

One of the advantages of powder coating is how good the finished product looks. Our quality assurance manager is actively looking for defects, problems with the powder or the product.

The second part of our appearance testing routine involves taking time to communicate with you, our customers. Every customer should have an idea of what he or she considers to be an acceptable finish, but it may take some discussion to determine what’s realistic and measurable. A finish standard can be as simple as no more than two visible surface imperfections per square foot. Or it can be no blisters or pinholes visible on the primary surfaces. Gloss and color standards may also be included. If a customer has very precise requirements, we can accommodate your needs.

Optional Quality Control Testing Methods

- Crosshatch Adhesion Text

- Salt Fog Corrosion Test

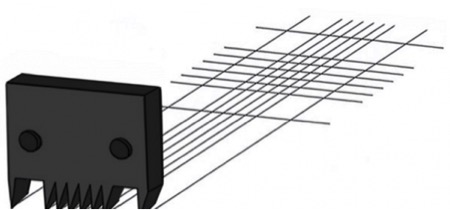

Crosshatch Adhesion Test

The Cross-Hatch Adhesion Test is a very popular test to assess the adhesion of the coating and essentially provides a visual assessment of the quality of the bond to the substrate.

The test is performed by making a series of cuts through the coating. Generally, 5 cuts are made with 5 sharp blades reasonably close together in one direction.

Then cut across that direction so you’ve cut through the paint to the metal five times left and right, and five times up and down. It should look like a tic-tac-toe grid when you’re done.

Once you have your tic-tac-toe grid, the pressure sensitive adhesive tape is applied to that area, pressed down, and then the tape is removed. That area is then judged to see if any paint was removed from the cross-sections that were cut. No coating removal is a good pass.

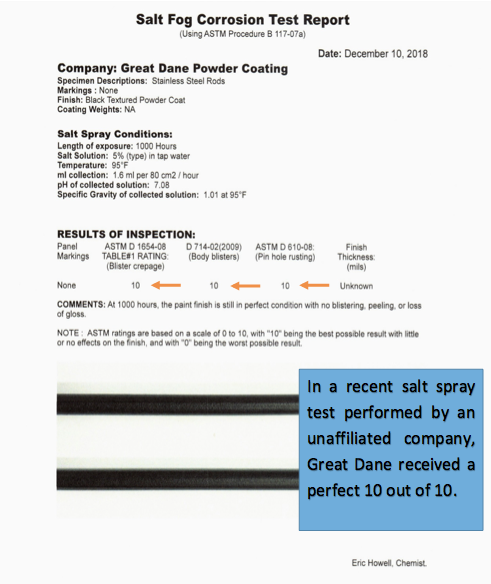

Salt Fog Corrosion Test

Interested?

Call us today at 724-537-9709 or click a button below.