Powder Coating Quality Control Testing

December 11, 2018

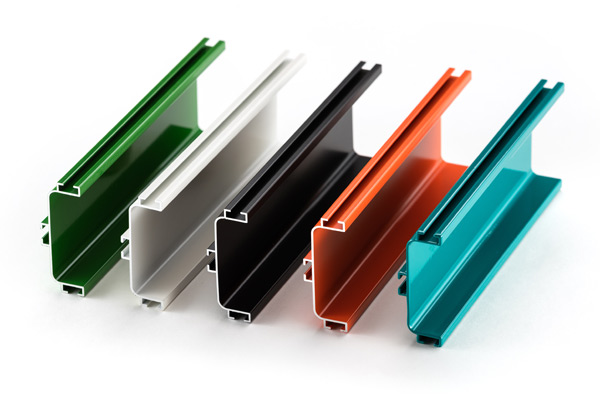

Different Types of Powder Coating

March 8, 2019All too often, custom racking is an afterthought.

Rodney Dangerfield, one of my favorite stand-up comedians, died years ago. He was made famous for the saying: “I get no respect.” Racking has often been referred to as the “Rodney Dangerfield” of the coating system components, since it rarely receives the respect it deserves.

Racking is sort of the red-headed step child of powder coating system. While the customer considers powder material, they usually overlook how we are going to hold the part or move them through system. Yet, poor racking can have an enormous impact on a coating line’s technical performance.

Racking should be considered a critical part of any coating project, one which deserves the respect of both the customer and coater.

Every great company that we have partnered with has had at least one of the following three GOALS:

Every great company that we have partnered with has had at least one of the following three GOALS:

- They need their product faster.

- They need their products to have better quality and/or less rack marks.

- They need a price reduction for their product.

In order to achieve this, racking considerations must play a key role.

With an upfront investment for the racking/tooling needed to complete your product, we can partner to achieve your GOALS.

Interested?

Call us today at 724-537-9709 or click a button below.