Electrocoating for Corrosion Resistance

December 13, 2022

Electrocoating Delivers Durability

January 15, 2023Powder Coating for Corrosion Resistance

Where there is Metal, there is Rust

Many people believe that metal rusts when it gets wet, and that washing vehicles and equipment too often leads to rust damage.

Others think that scratches and dents cause rust, or that road salt and harsh chemicals are the problem, or that storing equipment in places without climate control contributes to corrosion.

These common misconceptions contain a grain of truth, but the heart of the matter is that rust is iron oxide, and that means that oxygen causes iron and iron containing alloys to rust. Moisture is just the helper, a catalyst that accelerates the reaction.

Dents, exposure to water and harsh chemicals, road salt, and temperature changes serve as ways to expose metal to oxygen at higher concentrations and provide better opportunities for moisture and oxygen penetration.

Not all metals rust, but many still corrode, even aluminum and zinc; they just degrade in different ways and over a longer period of time. In fact, zinc corrodes on contact with aluminum in a galvanic reaction. Aluminum forms a “self-healing” surface oxide that actually helps protect the core of the metal.

In all cases, however, rust and corrosion lead in time to either structural failure or an unsightly surface appearance.

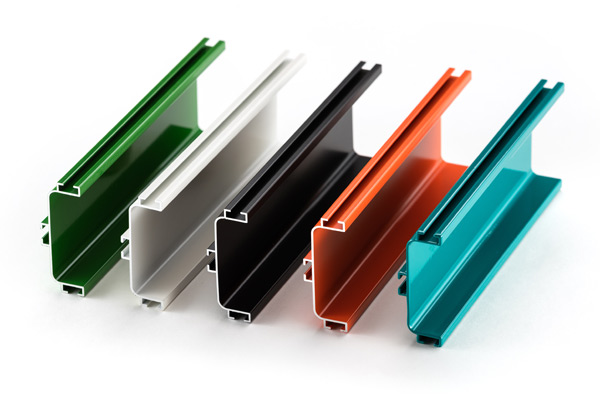

Powder Coating is one of the best and most effective methods of sealing metal surfaces away from contact with moisture, oxygen, and corrosive chemicals, all while providing a scratch and dent resistant surface that protects the metal even more over time.

Anti-Corrosion Powder Coating

At Great Dane Powder Coating, we serve American industry across a wide range of manufacturing disciplines, including: automotive, construction, defense, education, energy, food & beverage, manufacturing, and sports.

The manufacturing companies we partner with know that today’s powder coatings are designed to prevent oxidation by keeping the coated metal free of exposure to water and oxygen.

Powder coating delivers superior durability, scratch resistance, gloss retention, and resistance to chalking. It is especially useful for coating parts exposed to harsh environments and extreme weather conditions.

Unlike typical parts painting, powder coating is applied electrostatically and then cured under heat. Parts are prepared beforehand through sand-blasting or other surface preparation, removing any existing corrosion or chemicals deposited during the manufacturing process.

An expert powder coater, using a powder coating gun, usually sprays a number of similar parts racked together in a powder coating bay.

Our value-added services range from surface preparation and masking to labeling and packaging, and it’s no wonder that Great Dane Powder Coating is chosen by companies as quality driven as Spartan Motors, Caterpillar, and Manitowoc Cranes.

To find out if Great Dane Powder Coating is the right powder coating partner for your business, give us a call at 724-537-9709, or visit our Request a Quote page today.

Powder Coating Offers Many Advantages

Powder coating is chosen for many applications because it provides the temperature, corrosion, and chemical resistance needed across a range of manufacturing operations. Benefits include:

- A completely uniform and consistent coating with high durability.

- Powder coatings looks great and lasts for decades.

- Durable powder coating is scratch, chip, and flake resistant.

- Appliance coatings using powder coat can be anti-microbial, stain resistant, and even finger-print resistant.

- Significantly more chip and flake resistant than paint.

- Corrosion resistant in all weathering environments, from factory floor to city streets.

To find out if Great Dane Powder Coating is the right powder coating partner for your business, give us a call at 724-537-9709, or visit our Request a Quote page today.

What Great Dane Brings to the Table

When working with OEM manufacturers, Great Dane Powder Coating has the expertise to build a beneficial relationship that is cost and time effective, both mindful of your budget and aware of how we can help you improve processes.

When manufacturers involve their powder coater in the design process, we can recommend changes that avoid the cost of designing special racking systems for coating and that allow for the most efficient coating process. This can drive down cost and improve turnaround time.

Delivering Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our New Powder Coating Customer page today.

Interested?

Call us today at 724-537-9709 or click a button below.