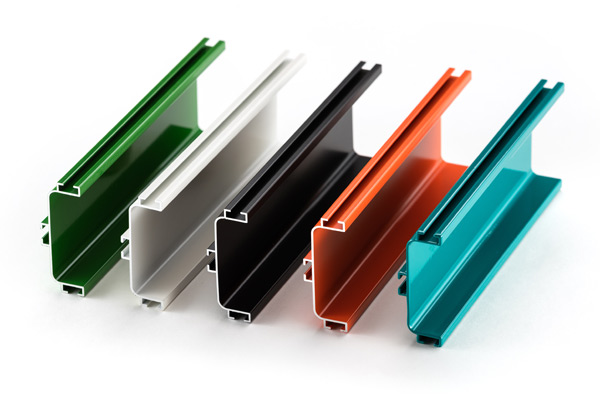

Powder Coating Aluminum Parts

November 28, 2022

Powder Coating for Corrosion Resistance

December 22, 2022Electrocoating for Corrosion Resistance

Corrosion Protection that Outperforms and Outlasts

Parts coatings serve a variety of functions. Today’s coatings are designed to help with wear resistance, friction reduction, and protection against caustic agents, as well as delivering a pleasing and long-lasting aesthetic appearance.

Among coating technologies like paint, polyurethanes, zinc primers, and chromate conversion, electrophoretic coating stands out as a growing technique embraced by many industries.

According to Polaris Market Research, electrophoretic coating enjoyed a global market share of $3.88 billion in 2021, and has a projected compound annual growth rate (CAGR) of 4.5% for the rest of the decade. One big reason for that is that in addition to providing a cost-effective, abrasion resistant, uniform coating, e-coating delivers superior corrosion resistance.

Rust-proof Environmental Protection

Many industries produce products that end up in challenging environments. Whether it’s the average car dealing with road salt in winter, agricultural equipment dealing with shed storage rust, or HVAC systems enduring the stress of everyday use, corrosive forces are everywhere.

E-coating is very resistant to damage from scratches and general wear and is superior to paint applications for preventing exposure to water vapor that can cause rust and corrosion.

E-coating is highly valued among manufacturers of fire trucks and emergency gear, where everything from vehicle bodies to complex parts can be expected to encounter corrosive chemicals, harsh environments, extreme fluctuations of temperature, and other challenges in emergency conditions.

Manufacturers of emergency vehicles know, e-Coat delivers superior corrosion and chemical resistance, while providing an excellent primer surface for powder coating or paint of any color or finish.

To learn more about how Great Dane can become a partner in e-coating your parts and products, call us at 724-537-9709 or visit our Contact Us page.

HVAC e-Coating

Another key industry that relies on electrocoating for corrosion resistance is the HVAC industry.

Heating and Air Conditioning systems work in corrosive environments every day. Average systems are exposed to humidity, salt, acidic agents in the atmosphere, and temperature stresses. Many HVAC systems have to survive in commercial environments, where they are exposed to a variety of industrial contaminants and emissions.

Corrosion is a common cause of failure in HVAC equipment, as it affects heat exchangers and condenser coils, which are difficult to coat.

Electrocoating has the answer. Because e-coating is applied via immersion in an electrically charged bath, it is excellent for coating complex shapes, like the coils in HVAC units. And because coating thickness can be controlled so precisely, the exact balance needed between protection and heat exchange performance can be achieved every time.

You can read more about how e-coating improves coil performance by reading our article on HVAC Coil Coatings. You can also call us at 724-537-9709 for more information.

Serving a Variety of Industries

Because e-coating delivers exceptional corrosion protection, the industrial applications go far beyond HVAC, agricultural equipment, and emergency gear. Wherever manufactured items face corrosive environments, e-coating plays a part in extending the service life and surface appearance of materials at risk for corrosion.

Additional applications include: military, maritime, automotive, mining, recreation, electrical equipment, construction, and factory floor machinery.

At Great Dane Powder Coating, our experience, capabilities, and responsive customer service make us an excellent partner in delivering consistent, durable e-coats that keep your production lines on schedule.

Delivering Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our NEW ELECTROCOATING CUSTOMERS page today.

Interested?

Call us today at 724-537-9709 or click a button below.