Great Dane Powder Coating is on the Winning Team

February 9, 2024

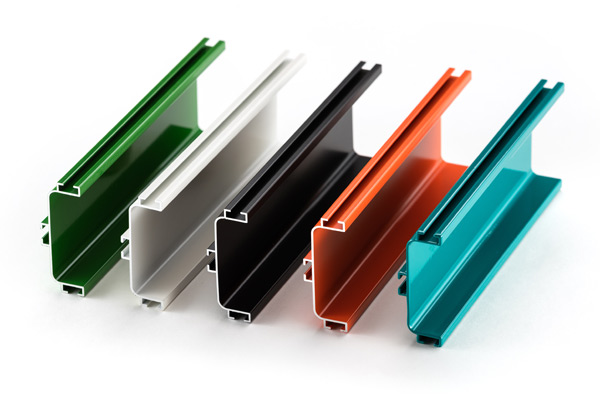

Powder Coating Aluminum Parts and Extrusions

March 11, 2024E-Coating for the Metal Furniture and Fixtures Market

Electrocoating Enhances Durability and Aesthetics

For makers of metal furniture and fixtures, the search for the most durable and long-lasting coating is constant. Manufacturers of metal cabinets, wire shelves, light fixtures, metal bed frames and similar products are always looking for solutions to both improve the appearance of their offerings and extend their lifespan.

E-coatings offer many advantages, ranging from unmatched corrosion resistance to a wide range of cosmetic applications. Epoxy coatings are ideal for products exposed to erosive factors such as moisture, sunlight, acidic rain, salt, and severe temperature fluctuations.

The E-Coating Process: A Primer

E-coating, also known as electrocoating, is method in which electrically charged particles of paint or epoxy are deposited from a water-based suspension onto a conductive part. This process guarantees a uniform coating across the entire surface, covering even the most intricate and complex shapes with a seamless finish.

Such precision and uniformity are often unachievable with traditional painting methods, making e-coating a preferred choice for a wide range of applications.

The electrocoating process begins with pretreatment, which prepares the surface of the metal for coating. This initial phase is critical for ensuring that any contaminants are removed, and the surface is conditioned to accept the e-coat. Following this, the item is submerged in the e-coat bath, where the application of an electric current causes the paint particles to adhere to the surface, creating a uniform layer. After the e-coating is applied, post rinses are employed to remove any excess paint, ensuring a clean and smooth finish. The final step involves curing the coat in an oven, a process that solidifies the coating, enhancing its durability and ensuring the finish remains consistent and resilient over time.

Benefits for Manufacturers

For manufacturers in the metal furniture and fixtures market, e-coating presents numerous advantages:

Uniform Coverage: E-coating’s ability to reach every nook and cranny of complex shapes ensures that every part of the product is equally protected from corrosion and wear.

Cost-Efficiency: High transfer efficiency and precise film-build control minimize waste, making e-coating a cost-effective solution for manufacturers.

Durability: With exceptional corrosion protection and a durable finish, e-coated products are more resistant to environmental stresses, reducing the need for frequent replacements, recoating, or repair.

Environmental Advantages: E-coating uses materials that are low in Volatile Organic Compounds (VOCs) and Hazardous Air Pollutants (HAPs), contributing to a safer working environment and minimizing the ecological footprint.

Aesthetic Flexibility: E-coating delivers a sleek, uniform finish that enhances the visual appeal of metal surfaces, providing a smooth and consistent appearance that stands out for its clarity and gloss. Its ability to coat intricately shaped objects evenly ensures that every detail is accentuated, highlighting the craftsmanship of the product without compromising on quality or durability.

Great Dane Powder Coating: Expertise in Electrophoretic Coatings

For many years, Great Dane Powder Coating Inc. has been known as a quality provider in delivering electrophoretic coatings to manufacturers. Working from a foundation of experience and a commitment to superior quality, Great Dane Powder Coating leverages the latest e-coating technology to deliver finishes that meet the highest standards of durability, appearance, and environmental safety.

The Great Dane process is finely tuned to handle a wide range of products, ensuring that each item, whether a metal cabinet, shelving unit, or lighting fixture, receives a coating that is both protective and visually appealing. Our company’s expertise in e-coating chemistry and application techniques makes Great Dane a valuable partner for manufacturers looking to enhance the quality and longevity of their products.

Conclusion

The metal furniture and fixtures market demands solutions that combine aesthetic appeal with long-lasting durability.

E-coating, with its numerous benefits, stands out as an ideal choice for manufacturers aiming to meet these demands. Great Dane Powder Coating’s expertise in providing electrophoretic coatings further ensures that products not only stand the test of time but also meet the evolving needs of our clients. As this technology continues to evolve, its role in manufacturing durable, attractive, and environmentally friendly metal furniture and fixtures is set to grow, marking a promising future for the industry.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our New ElectroCoating Customer page today.

Interested?

Call us today at 724-537-9709 or click a button below.