Expedite Your Parts Coating

June 24, 2022

Advanced Coating Technologies

July 25, 2022The Challenges of Powder Coating

All Powder Coating Shops are Not the Same

Every powder coating shop is different, and every powder coating job has its own challenges. When choosing the right service partner for your manufacturing operation, consider the many different challenges that experienced powder coaters must overcome.

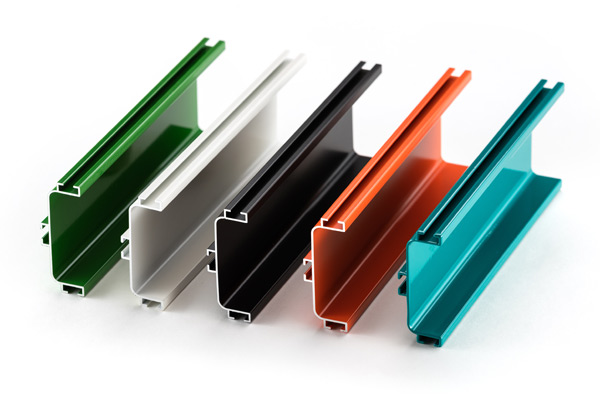

Powder coating is an attractive, low maintenance and cost-effective process for finishing most metals. A powder coating shop must cope with large volumes and high-quality requirements, with throughputs ranging from several hundred to thousands of pieces in one shift. As a result, they must have the flexibility to handle a wide range of jobs and be able to adapt quickly when part specifications change.

Common Powder Coating Defects

Poor powder coating results are usually associated with a common theme: inexperience, aging or poor equipment, and improper preparation. Let’s take a look at a few specifics.

- Blooming. This is a classic problem and is especially common in commercial applications. Blooming is a white, powdery residue that forms on the surface of the coating and can appear during cure or on top of cured coatings. Blooming occurs sometimes because the resin used is either not cured properly or it’s too low in quality.

- Outgassing and Cratering. Moisture on improperly prepared parts can create a pock-marked finish during curing. Cratering, which looks as bad as it sounds, is often the result of contaminants on the substrate, in the powder used, or both.

- Blushing and Framing. Blushing is caused by contaminants on the substrate —anything from label glue to a pen mark— pushing discolorations through to the surface. Framing is a discoloration caused by improper film build up at the edges of a piece.

- Hazy Finish. Cheap powder resin and/or curing the parts at an improper temperature or in humid conditions can result in a foggy, hazy look to the cured coating.

- Gun Spitting. During application, the spray gun spits a chunk of powder against an otherwise smooth surface, ruining the coating.

- Orange Peel. Orange peel is a common phenomenon in powder coating, and it can ruin an otherwise fantastic finish. It happens when incomplete coverage occurs, due to poor paint delivery or overspray

At Great Dane Powder Coating, Inc., we know there are a hundred ways to do a poor job and a very narrow path to delivering the high-quality, durable finish that makes your investment in powder coating worthwhile.

In 2021, Great Dane Powder Coating ran 1,326,401 parts, with only 18,414 reworks. Out of 1.3 million parts, our success rate stands at 98.7%, a remarkable accomplishment. We are proud of our dedicated team and congratulate them for this achievement. You can count on Great Dane to deliver the same standard of excellence for your next project.

Delivering Powder Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our NEW POWDER COATING CUSTOMERS page today.

Interested?

Call us today at 724-537-9709 or click a button below.