Avoid Electrocoating Defects

February 6, 2023

E-Coat Masking Tips to Avoid Costly Errors

March 7, 2023Masking Threaded Holes Before Powder Coating

Have Your Powder Coated Parts been Ruined by Bad Masking?

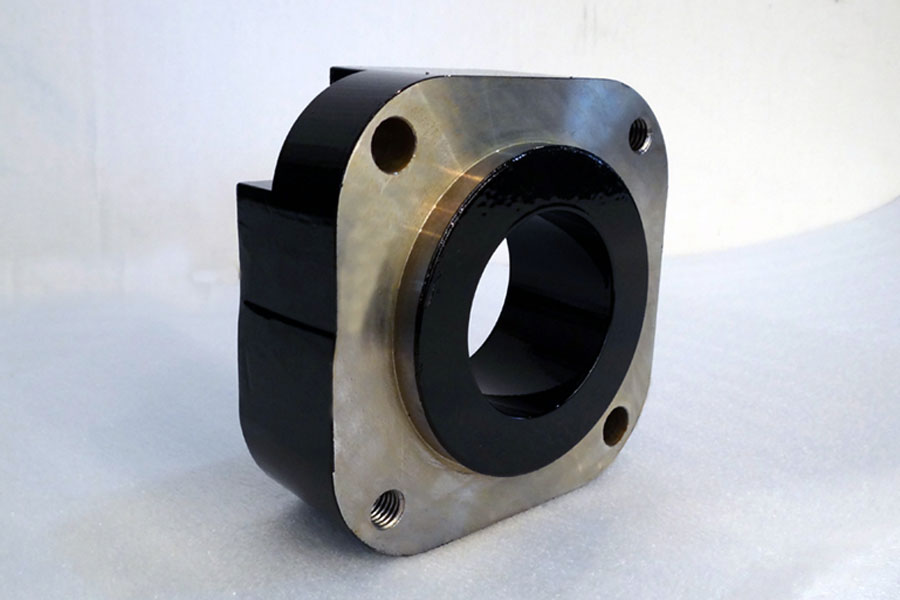

When powder coating parts, whether for automotive production, appliances, or heavy equipment manufacture, coated holes and fouled threads and can be a problem.

If the initial attempt at masking failed, the part may have to be cleaned of its powder coat using an industrial stripper before beginning again, the threads chased or re-tapped, or the part order scrapped completely.

Depending on when in the process the error is found, the costs of the error mount. Overspray that isn’t immediately apparent can still cause problems when subassemblies are put together, especially if tolerances are tight. Overspray can even cause cross-threading when contaminated portions of the threads cut new threads in the opposite piece.

At Great Dane Powder Coating, we have decades of experience in establishing high-quality protocols for our powder coating line, assuring that masking is precise and finished parts meet your exacting specifications.

Call us at 724-537-9709 or visit our Contact Us page today.

Working With You as a Powder Coating Partner

What’s the best way to assure that your parts receive the highest quality, most precise powder coat, coatings that save time and money through reliable and consistent deliveries?

The answer is working with your powder coater as a partner rather than simply a third-party service or a catalog order company. When you call on the expertise of the powder coating experts at Great Dane, we work with your engineers to understand the practicalities behind the specifications.

We take a consultative approach, learning about your manufacturing process and the intended life-cycle of the parts to be powder coated.

Even the production cycle for the parts and their powder coating schedule can have an effect on doing the job properly. Masking plugs and caps, for example, exhibit varying degrees of wear depending on frequency of uses, bake temperatures, and substrate hardness. Silicon and EDPM rubber both dry out over repeated bake cycles, cracking and crazing in ways that can cause the plug to fail.

Making the best decision for the customer involves more than following the specifications on a single order.

Experience is the Best Teacher

Your current powder coater may have experience with masking threaded through holes. But what about blind holes? Do they know the differences between masking leading threads and exit threads; how die cuts might be used as masks; or the problems that silicone residue/volatiles can introduce during the curing process?

Some powder coaters have yet to master the subtleties of masking. They don’t know if the plug should be jammed in tight or just enough to fill the hole. They may leave the plugs and masks on all the way through curing, when for some jobs a better edge can be achieved by pulling plugs part way into the curing process.

Doing the job right is often about calling on years of experience to bring the right processes to the specific job at hand.

28 years of service make Great Dane Powder coating an excellent resource for manufacturers needing the high-quality results that powder coating is famous for.

If you’re not getting the best results from your current powder coater, give us a call at 724-537-9709 or visit our Contact Us page today. We’re ready to work hand-in-hand with your manufacturing team to deliver reliable and outstanding results.

Delivering Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our New Powder Coating Customer page today.

Interested?

Call us today at 724-537-9709 or click a button below.