5 Great Tips for Choosing the Right Powder Coating Service

March 21, 2023

What Makes e-Coating a Good Finishing Process?

April 16, 2023Advantages of Powder Coating vs. Traditional Parts Painting

Eliminate Paint Drying Time, Minimize Touch-up

Powder coating and traditional parts painting are both methods of applying a protective coating to surfaces, and both are well understood and well-integrated into industrial production.

But the market for powder coating continues to grow. According to a report in MarketsandMarkets.com, powder coating is growing at a compound annual growth rate (CAGR) of 5.2%, reaching a worldwide market value of $19.9 billion USD by 2028.

What are the advantages of powder coating that make it such an attractive choice for manufacturers today?

To start, powder coating is more efficient. Because powder coating is an electrostatic process, coatings can be applied more evenly and with less opportunity for runs and drips. Where paint drying time can be hours or days, depending on the paint mix and application, powder coating is dried in one pass through a special oven, usually lasting only 20 to 30 minutes.

Powder Coating Beats Paint in These Areas

- Durability: Powder coating creates a thicker and more durable coating than traditional painting. This makes it more resistant to chipping, scratching, and fading.

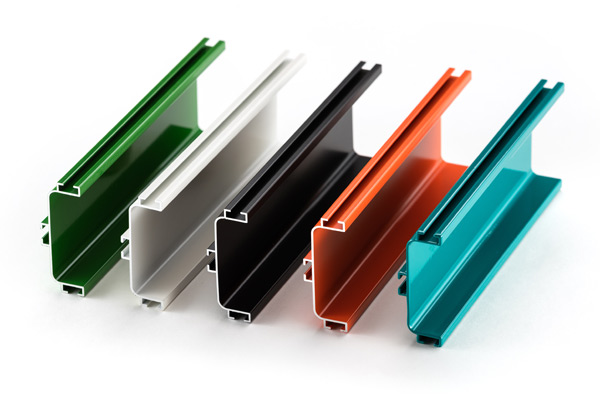

- Versatility: Powder coating can be used on a variety of metals and fiberglass materials, and it comes in a wide range of colors and finishes.

- Cost-effective: The cost of powder coating materials is often lower than using traditional painting techniques. Additionally, the durability of the coating means that it will need to be reapplied less frequently, resulting in long-term cost savings.

- Environmentally friendly: Powder coating produces less waste and is more environmentally friendly than traditional painting. The powder is electrostatically charged and adheres to the surface without overspray, reducing waste and the need for solvents.

Consistent Coatings Over Multiple Production Runs

Among the best features that make powder coating so attractive for manufacturers are: uniformity, control, and repeatability. That means order to order and batch to batch, consistent results can be delivered that fit well with the demanding specifications of most manufacturing processes.

These benefits are possible because powder coating is applied in a controlled and uniform manner, with a process that can be monitored and adjusted to maintain the desired finish.

Once a powder coating recipe has been established, it can be easily replicated from batch to batch. This means that the same finish can be achieved consistently, including uniform properties of viscosity and texture. This ensures that each coating will have the same characteristics and appearance, regardless of when they were applied.

Call Great Dane Powder Coating at 724-537-9709 or visit our Contact Us page today.

Put Parts Painting in the Past

Isn’t it time to put the many problems associated with parts painting in the past? With powder coating, you don’t have to deal with inconsistent finishes, the cost of multiple coats and touchups, and delays with drying time and the paint contamination that can happen when the product is still wet.

Powder coating is also better for the environment (no volatile organic compounds), less wasteful, and requires no cleaning solvents. Call Great Dane Powder Coating at 724-537-9709

Delivering Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufacturers across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our New Powder Coating Customer page today.

Interested?

Call us today at 724-537-9709 or click a button below.