HVAC Coil Coatings and More

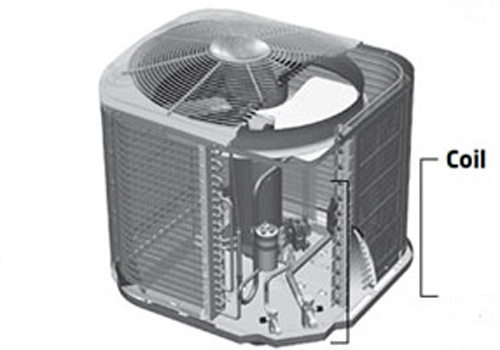

Coil Coating Protection for Evaporators, Radiators, Heat Exchangers…

At Great Dane, our new state-of-the-art electrocoating facility is fully operational and serving the needs of manufacturers producing coils and complex shapes, including the HVAC industry.

E-coating is a high-tech “wet” process where metal parts are immersed in a bath of paint and epoxy. An electric current is applied to attract the particles to the metal, after which the part is cured in an oven.

At Great Dane, our expertise includes durable, corrosion resistant coatings for:

- Heat Exchangers

- Refrigeration Coils

- Radiators

- Finned Tube Coils

- Evaporators

- Condenser Coils

- Fans & Blowers

- Air Handling Equipment

- Fabrications & Weldments

Interested in learning more, give us a call at 724-537-9709 or complete the contact form on this page today.

Advantage of Electrocoating

The benefits of electrocoating (E-coating) include superior corrosion resistance, controllable, uniform film coverage, and the ability to coat complex parts evenly. An added advantage of the E-coat process is its high efficiency. As many parts as can be racked can be coated at once.

- Penetrates hard-to-reach areas and sharp metal edges.

- Virtually all unused paint is recoverable

- Coating thickness is precisely controlled, leading to consistent and uniform coats across multiple product runs.

E-coating is an eco-friendly process and is EPA compliant.

Read Our Articles on Electrocoating

We have a number of articles on electrocoating for your information. Here are a few links:

- Identifying and Addressing Electrocoating Defects

- Controlling Film Thickness

- Volume Electrocoating

- Coatings for Complex Shapes

- Masking for Electrocoating

- When is Electrocoating the Best Option?

Having trouble getting your orders completed on time? Give us a call at 724-537-9709 or complete the contact form on this page today. Great Dane is ready to serve.