Powder Coating in Appliance Manufacture

October 25, 2022

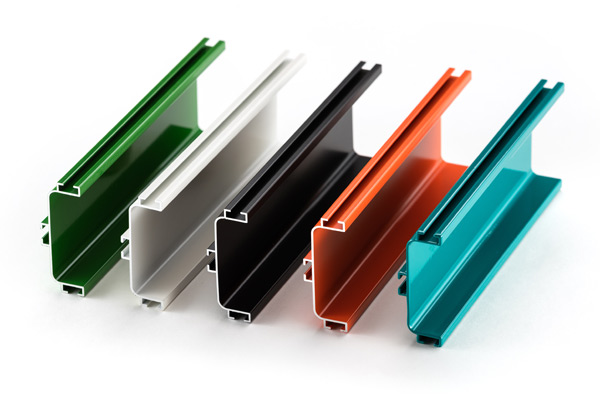

Powder Coating Aluminum Parts

November 28, 2022Can You Electrocoat Aluminum?

e-Coating Has Been Widely Adopted for Aluminum Parts

Electrophoretic coating has become a popular surface finishing for aluminum parts. The process is also called electrolytic coating, or just “e-coat” for short.

It takes less time to e-coat aluminum and delivers a very high adhesion to the substrate when compared with other methods such as anodizing and chromate conversion.

An e-coat finish is durable, scratch resistant, and highly corrosion resistant, as well as being economical when compared with other surface treatments.

One big advantage of e-coating is the ability to coat complex shapes with a precise coating thickness.

The e-Coating Process

Aluminum parts are generally handled using cathodic e-coating. Electrically charged paint (or epoxy) is deposited on an conductive aluminum substrate dipped in a coating bath. By applying a direct current, the positively charged coating is deposited at the negatively charged cathode (the aluminum part).

In practice, this is done using by hanging many uniform parts from a rack and dipping the entire rack at once into the e-coat bath, which generally consists of 80-90% deionized water and 10-20% dissolved e-coat.

By controlling the electric current applied, a very precise and uniform coating film thickness is achieved.

As each rack of parts exits the e-coat bath, the parts are rinsed to remove any residue from the bath and are moved to a bake oven that serves to cure the film and maximize its performance properties.

To learn more about how Great Dane can become a partner in e-coating your aluminum parts and products, call us at 724-537-9709 or visit our Contact Us page.

Automotive and Aluminum Parts Industries

Today, e-coating is extensively used in the automotive industry for coating automobile parts and components.

The automotive industry relies on many other sectors to support it in manufacturing and delivering high quality vehicles, and electrocoating is a prime example. To achieve the durability and service life expected of today’s cars and trucks, parts coatings must be strong, durable, and consistently applied across large production runs. Electrophoretic coating achieves this with fast turnarounds, repeatable precision film thickness, and cost-effective production runs.

E-coating is also used as a primer before painting, to deliver high corrosion resistance over years of on-the-road exposure to weather, harsh chemicals, and even rough off-road environments.

Because aluminum has a high strength-to-weight ratio, but only about one-third the density of steel, aluminum extrusions are often used to produce the structural elements of modern vehicles.

Indeed, any manufacturing process that produces aluminum extrusions can benefit from electrocoating.

An Environmentally Friendly Process

At Great Dane, we know that many of our larger manufacturing partners appreciate the fact that electro-coating is environmentally friendly.

Unlike traditional paints and liquid coating processes, e-coating uses no solvents. This means there is no outgassing from harmful VOCs (Volatile Organic Compounds). Nor is there significant waste product, as e-coating can achieve efficiencies above 95%.

The automobile industry, worldwide, is committed to sustainability and environmentally conscious solutions through the use of recycled materials, waste reduction, energy management, water conservation, and responsible sourcing.

As a coatings partner with many industry leaders, Great Dane too is committed to supporting the environmental goals of our manufacturing and fabrication customers, and e-coating is a significant technology in helping to achieve those goals.

Delivering Coating Excellence for over 28 Years!

At Great Dane Powder Coating, Inc., we have more than a quarter century of experience under our belts. We offer the benefits of a cutting-edge facility and high-end equipment for providing exceptional results.

It’s no wonder that we are trusted by fabrication facilities and manufactures across the country to deliver highly durable coatings on a wide variety of parts and components.

When you want affordable, reliable, and outstanding results, give us a call at 724-537-9709 or visit our NEW ELECTROCOATING CUSTOMERS page today.

Interested?

Call us today at 724-537-9709 or click a button below.