Meet Kendrick Bolish, Great Dane’s New Quality Manager

October 3, 2025In the ever-evolving world of manufacturing and finishing, e-coating stands out as a game-changer. E-coating, or electrophoretic painting, provides a uniform, durable finish that outperforms many traditional methods, making it a favorite in industries like automotive and electronics.

But like any technology, e-coating isn’t without its drawbacks. While it promises excellent corrosion resistance and cost-effectiveness, it also demands significant initial investment and precise control over the process. This dual nature makes it crucial for businesses to weigh their options carefully. Whether you’re considering e-coating for its protective qualities or its eco-friendly appeal, understanding its pros and cons will help you make an informed decision. Let’s look deeper into what makes e-coating a compelling choice and where it might fall short.

Understanding E-coating

E-coating, or electrophoretic deposition, involves an electrically charged paint bath used to coat metal surfaces. This technology ensures an evenly distributed finish by using an electric current to attract paint particles to the product surface. It’s notable for its uniformity, corrosion resistance, and efficiency in complex geometries.

Process Overview: The e-coating process begins with a power source that directs an electrical current through a water-based paint solution. Metal components submerged in this solution attract the paint particles due to their opposite charge. After the bath, a rinse stage removes excess paint, followed by curing in an oven to harden the coating. This result yields a consistent, durable finish.

Materials and Applications: Commonly used in the automotive, electronics, and appliance industries, e-coating supports various paints and substrates. Steel, aluminum, and galvanized surfaces benefit from its anti-corrosive properties, making the process suitable for parts where durability and longevity are priorities.

Environmental Impacts: As a water-based process with low volatile organic compounds (VOCs), e-coating presents a sustainable alternative to traditional painting methods. Waste reduction and energy efficiency align with environmental regulations, enabling businesses to meet green initiatives.

Recognizing both the benefits and challenges of e-coating supports strategic decision-making for potential adopters. This technique, with its precision and protective qualities, continues to redefine industry standards, particularly for manufacturers prioritizing efficiency and sustainability.

Pros of E-coating

E-Coating offers various advantages in industrial applications. Stakeholders, from automotive to electronics sectors, value these benefits for improved product longevity and sustainability.

Superior Corrosion Resistance

E-coating significantly enhances corrosion resistance. When e-coating is applied, it creates a consistent barrier against environmental factors like moisture and chemicals. This uniform layer ensures that every part of the surface is protected, which is crucial for metal components exposed to harsh conditions. Industries prioritizing durability will find e-coating particularly beneficial, minimizing corrosion-related failures.

Uniform Application

E-coating delivers a uniform finish across complex geometries and intricate parts. The electrically charged paint particles deposit evenly on all surfaces, including recesses and sharp edges. This ensures a complete and consistent coating, reducing the risk of flaws that might cause defects or quality issues. The uniformity obtained with e-coating surpasses traditional techniques, enhancing a product’s aesthetic and functional properties.

Environmental Benefits

E-coating aligns with environmental standards by reducing volatile organic compounds (VOCs) and hazardous waste. The water-based nature of the coating process minimizes harmful emissions, contributing to a cleaner production environment. Companies implementing e-coating demonstrate a commitment to sustainable practices, meeting regulatory requirements while appealing to eco-conscious clients. This eco-friendly approach supports long-term sustainability goals in manufacturing.

Cost-Effective Solution

E-coating is a cost-effective method over time. The high transfer efficiency of the e-coating process, coupled with reduced waste, decreases material costs.

Cons of E-coating

While e-coating offers numerous advantages, it’s essential to consider the potential drawbacks.

Limited Color Options

E-coating primarily uses water-based paints that limit color options compared to traditional coating methods. While suitable for industrial applications where color is less critical, this limitation poses challenges in sectors like consumer goods or custom manufacturing, where specific hues are vital. Custom formulations incur additional costs and extension of lead times for paint production. To mitigate these challenges, companies frequently view secondary finishing processes, adding layers of complexity and expense.

Thickness Limitations

The E-coating process results in thin, uniform coatings ranging from 15 to 35 micron (.5 – 1.3 mil). While advantageous for intricate parts and corrosion protection.

Applications of E-coating

E-coating, known for its efficiency and sustainability, plays a crucial role across various sectors. By providing a uniform, corrosion-resistant finish, e-coating meets the demanding standards of modern industries.

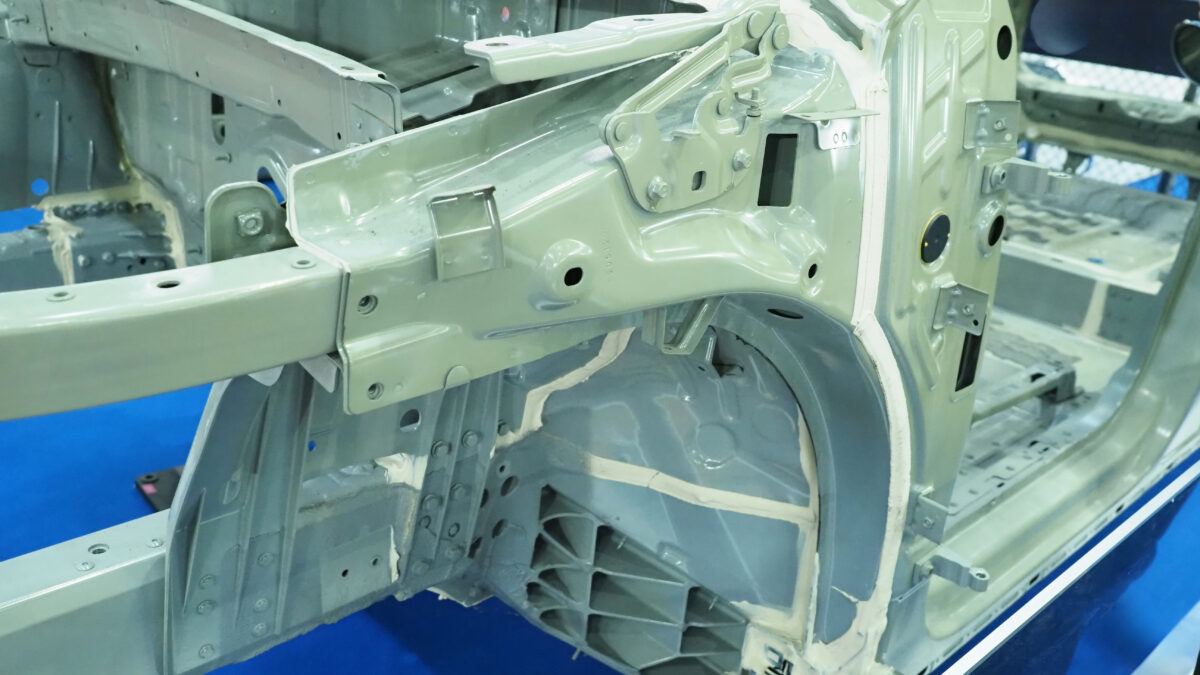

Automotive Industry

E-coating is vital in the automotive industry due to its superior protective qualities. It’s applied to vehicle chassis, body panels, and other components to create a robust barrier against corrosion. E-coating enhances durability, ensuring vehicles can withstand harsh environmental conditions. Given the industry’s focus on sustainability, e-coating’s low VOCs and waste reduction align with its environmental goals. Moreover, the uniform application of e-coating improves vehicle aesthetics and reduces the likelihood of defects, providing a seamless finish that reflects quality and precision.

Consumer Goods

In consumer goods, e-coating provides a versatile solution for protecting and enhancing product surfaces. It’s commonly used in appliances, furniture, and electronic devices, offering a durable finish that resists wear and prolongs product life. Because consumer goods often face varying environmental conditions, e-coating’s ability to deliver consistent protection is invaluable. The environmental benefits of e-coating also appeal to brands prioritizing sustainability in their operations. While the variety of colors may be limited, the practicality and protection offered by e-coating outweigh aesthetic constraints, making it a preferred choice for high-volume production.

E-coating stands out as a transformative technique in the manufacturing world offering numerous benefits like environmental friendliness and cost-effectiveness. Its ability to provide a uniform durable finish makes it a popular choice in industries such as automotive and electronics. However the initial investment and specific limitations like color options and coating thickness need careful consideration. For businesses aiming to enhance sustainability and efficiency e-coating presents a compelling option that aligns with modern manufacturing goals. Balancing the pros and cons is essential for any company considering this innovative technique to ensure it meets