E-Coat: Electrophoretic Coating Solutions

Electrophoretic, E-Coating, Exceptional Protection

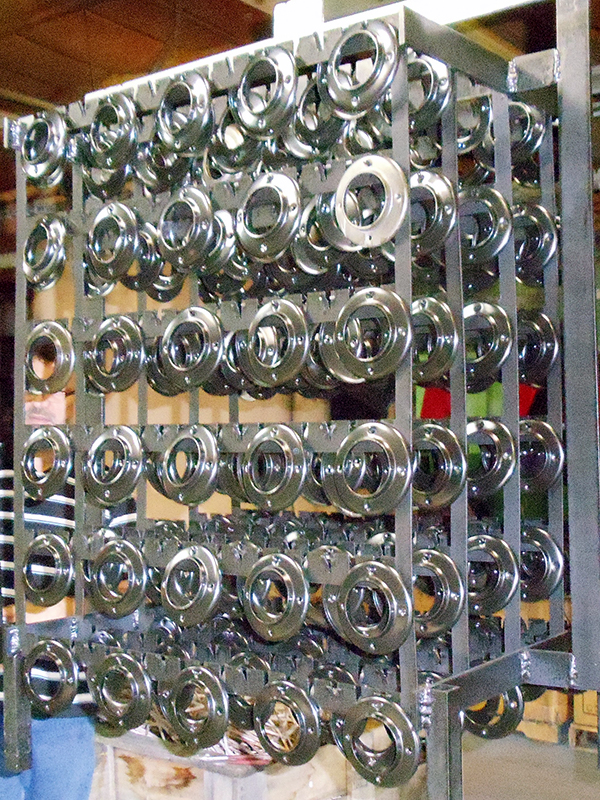

E-coating (also referred to as electrophoretic painting, electrocoating, and electropainting) is a cutting-edge finishing process designed to provide superior corrosion resistance, consistent coverage, and long-lasting durability. While powder coating uses a dry powder that is sprayed onto a surface, e-coating is a wet process where metal parts are completely submerged in a bath of paint and epoxy. An electric current is then applied, drawing the coating particles evenly to the surface of the metal. The coated part is finally cured in an oven to create a hard, protective finish.

This process was first developed for automotive applications to protect steel car bodies from corrosion, but today e-coating is used across multiple industries, including manufacturing, agriculture, construction, and consumer goods. Its ability to deliver precision, uniformity, and efficiency makes it a top choice for both high-volume production runs and specialized components.

Advantages of E-Coating

Choosing e-coating offers several unique benefits compared to other coating methods:

Excellent coverage for complex shapes: E-coating ensures even application, even on recessed or hard-to-reach areas.

Precise film thickness control: Adjusting the electrical current allows for highly predictable coating thickness.

Thin yet durable coatings: The electrophoretic process makes it easier to achieve thinner, uniform layers that remain protective.

High efficiency and utilization: Nearly 100 percent of the coating material is used, minimizing waste.

Enhanced corrosion protection: E-coating is often used as a primer layer to improve the durability of topcoats and extend the life of parts.

Perfect for high-volume production: Its consistency and automation make it ideal for large runs without sacrificing quality.

Environmentally friendly process: Because it is water-based, ecoating avoids flammability issues and reduces environmental impact.

The e-coat process was originally developed for applying an anti-corrosive coating over steel car bodies and has become an important tool for a variety of parts.

How E-Coating Works

The e-coating process begins with a bath of water-based coating materials, which include resins, pigments, and additives. The parts are fully immersed in this bath, and an electrical current is applied. The part itself becomes an electrode, which causes the resin near its surface to lose water solubility and deposit evenly as a protective layer.

Once coated, the parts are removed from the bath and placed in an oven where the finish is cured into a durable, lasting surface. The process is efficient, repeatable, and adaptable to different part sizes and shapes.

Because e-coating is water-based, there are no flammability risks during application, and parts that have been pretreated with water-based cleaning solutions do not need additional drying.

Advanced Developments in E-Coating

Modern advancements in electrophoretic coating technology continue to expand its capabilities. Today, e-coating materials can include:

- Low-voltage organic primers for even better corrosion resistance.

- UV-protective coatings to guard against sunlight exposure.

- Formulations designed for improved edge coverage and smoother finishes.

These innovations make e-coating more versatile than ever, serving industries that demand both aesthetics and long-term performance.

Why Choose E-Coating?

For manufacturers seeking efficiency, durability, and consistent quality, e-coating is the process of choice. Whether used as a stand-alone finish or as a primer layer beneath powder coating or paint, it delivers exceptional value. With nearly complete material utilization, superior protection, and reliable performance, electrophoretic coating continues to be one of the most effective finishing technologies available.

Our Service Area

Great Dane Powder Coating provides high-quality metal painting services to customers throughout the Pittsburgh region, Western Pennsylvania, Eastern Ohio, West Virginia, Maryland, and New York.

We have clients in Cranberry, Erie, Greensburg, Indiana, Johnstown, Latrobe, Pittsburgh, and Washington, as well as Cleveland Ohio and Morgantown, West Virginia.

Interested?

Call us today at 724-537-9709 or click a button below.